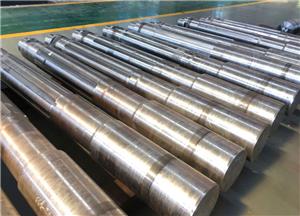

4330v Forged Vavle Pump Body For Oil Equipment

- HHF

- HENAN

- 45DAYS

- 200pcs per month

Quality first is our principle.

HHF has been certified by API Q1 Quality Management System.

Customers are very satisfied with our high quality. Our technologists can design the drawings as per customers' requirements.

4330v Forged Vavle Pump Body For Oil Equipment

Pump head body

Smelting chemical composition of steel

Grade | C | Si | Mn | P | S | Ni | Cr | Mo | V | Cu | Nb |

25Cr2Ni4MoV | 0.24 ~ 0.30 | 0.15 ~ 0.30 | ≤ 0.50 | ≤ 0.015 | ≤ 0.015 | 3.50 ~ 4.00 | 1.40 ~ 2.00 | 0.30 ~ 0.60 | 0.08 ~ 0.15 | ≤ 0.20 | / |

30CrNi2MoV | 0.28 ~ 0.33 | 0.15 ~ 0.33 | 0.50~ 0.80 | ≤ 0.015 | ≤ 0.015 | 2.40 ~ 2.70 | 0.90 ~ 1.10 | 0.40 ~ 0.55 | 0.06 ~ 0.12 | ≤ 0.20 | / |

30CrNi3MoV | 0.26 ~ 0.33 | 0.15 ~ 0.35 | 0.30~ 0.90 | ≤ 0.015 | ≤ 0.015 | 2.80 ~ 3.30 | 0.80 ~ 1.50 | 0.40 ~ 0.60 | 0.06 ~ 0.25 | ≤ 0.20 | / |

17-17PH ( Stainless steel) | ≤ 0.07 | ≤ 1.00 | ≤ 1.00 | ≤ 0.025 | ≤ 0.010 | 3.50-5.00 | 15.00-17.50 | / | / | 3.00-5.00 | 0.15-0.45 |

Mechanical properties should meet

Grade | Yield Strength Rp0.2(M p a) | tensile strength Rm(M p a) | Elongation A(%) | Shrinkage rate Z(%) | Charpy impact energy AKV2( J) | Reference hardness ( HB ) | |

20 ℃ | -40 ℃ | ||||||

25Cr2Ni4MoV | ≥ 1050 | ≥ 1120 | ≥ 12 | ≥ 35 | Single value ≥ 33 | Average ≥26 | 305-380 |

Single value≥20 | |||||||

30CrNi2MoV | ≥ 880( longitudinal ) | ≥ 1020 ( longitudinal ) | ≥ 12 | ≥ 35 | Average value ≥ 42 | Average value ≥ 34 | 280-360 |

≥ 860( horizontal ) | ≥ 960 ( horizontal ) | Single value≥34 | Single value ≥27 | ||||

30CrNi3MoV | ≥ 900 ( longitudinal ) | ≥ 1050 ( longitudinal ) | ≥ 14 | ≥ 35 | Average value ≥ 42 | Average value ≥ 34 | 290-360 |

≥ 880( horizontal ) | ≥ 1000 ( horizontal ) | Single value≥34 | Single value ≥27 | ||||

17-17PH ( Stainless steel) | ≥ 900 | ≥ 1000 | ≥ 14 | / | Single value ≥ 18 | / | / |